How to Choose the Right Rubber Material for Automotive Applications

When it comes to automotive applications, choosing the right rubber material is crucial for ensuring durability, safety, and performance. The right material must meet the specific requirements of automotive components, which include resistance to heat, oil, wear, and the environmental conditions they will be exposed to. Below are key factors to consider when choosing the right rubber material for automotive applications:

1. Material Resistance

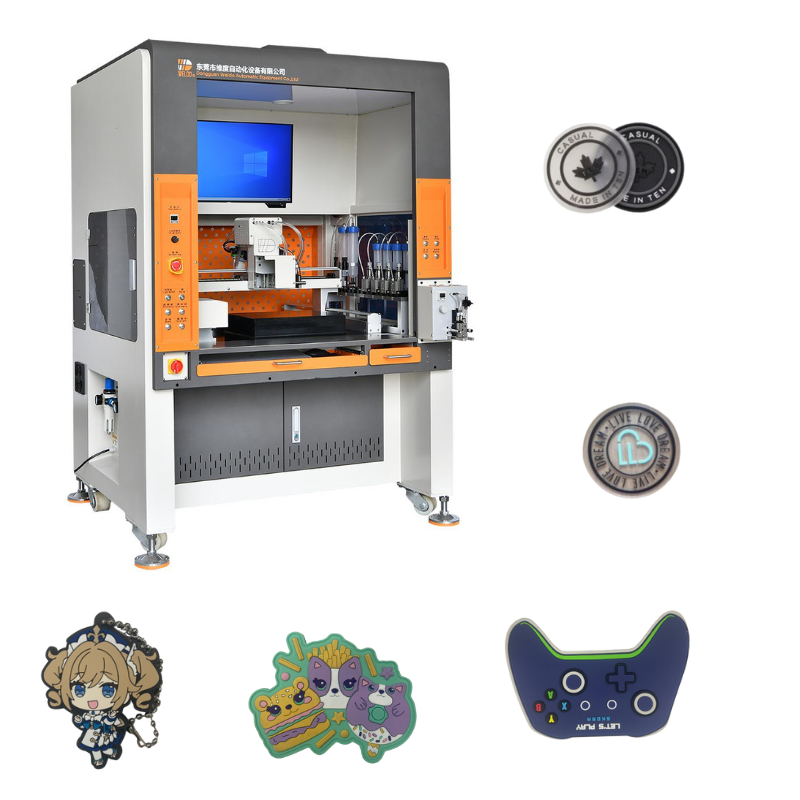

In automotive manufacturing, rubber components such as seals, gaskets, and hoses need to withstand exposure to various chemicals, oils, and heat. For example, if you're dealing with Kawaii Emoji soft PVC keychain filling machine parts, they should be resistant to degradation from oils and automotive fluids.

- Oil Resistance: Certain rubber materials, like nitrile rubber (NBR), are ideal for automotive components exposed to oils, fuels, and lubricants.

- Heat Resistance: Silicone rubber offers excellent heat resistance, making it perfect for engine components and other high-temperature applications.

2. Durability and Strength

Automotive rubber parts often undergo heavy wear and tear, particularly in high-stress environments like suspension systems or engine compartments. For components like smiley face soft PVC keychain filling machine parts, the material must have superior durability to resist wear over time.

- Tensile Strength: Materials like EPDM (ethylene propylene diene monomer) are known for their high tensile strength, making them suitable for automotive seals and gaskets.

- Elasticity: The ability to return to its original shape after deformation is important, especially for rubber used in dynamic applications such as Mini Emoticon soft PVC Keyrings filling machine.

3. Environmental Resistance

Rubber materials used in automotive applications must also be resistant to environmental factors like UV rays, ozone, and moisture. Components like Mini Emotion soft PVC Keyrings filling machine need to maintain their integrity even under harsh weather conditions.

- UV Resistance: Neoprene rubber offers good resistance to UV degradation, ensuring that rubber parts in cars will not become brittle or crack due to sun exposure.

- Ozone Resistance: Materials such as EPDM are also resistant to ozone, which can cause rubber to crack and degrade when exposed to the atmosphere over time.

4. Cost-Effectiveness

Cost plays a crucial role in the selection of rubber materials, especially for mass production of automotive parts. While premium materials like silicone rubber offer excellent performance, they may not always be cost-effective for every application. Therefore, choosing a material like Kawaii emoji soft PVC keychain filling machine material for less demanding parts might be more cost-effective without compromising on functionality.

- Cost vs. Performance: Evaluate the performance requirements of each automotive part and balance the cost with the necessary properties such as heat, chemical, and ozone resistance.

5. Application-Specific Requirements

Every automotive part has unique requirements. Whether it’s a seal, gasket, or keyring, understanding the specific function and performance needs of the part is crucial. For example, the Kawaii Emoji soft PVC keychain filling machine needs to be durable yet lightweight, making soft PVC an ideal choice for decorative automotive components.

Contact:

Email: weldomolly@gmail.com

WhatsApp: +86 15173143190

READ MORE:

- Top Factors for Customizing Automotive Rubber Seals for Keychain Filling Machines

- How to Choose the Best Rubber Materials for Automotive Gasket Applications

- Selecting the Best Rubber Material for Automotive Seals and Gaskets

- Critical Aspects to Consider for Automotive Rubber Seals in Keychain Filling Machines

- Essential Factors to Consider When Customizing Automotive Rubber Seals for Keychain Filling Machines

- Key Factors to Consider When Customizing Automotive Rubber Seals for Keychain Filling Machines

- Top Considerations for Customizing Automotive Rubber Seals in Keychain Filling Machines

- How to Customize Automotive Rubber Seals for Keychain Filling Machines

- Key Factors for Customizing Automotive Rubber Seals in Keychain Filling Machines